Final Report:

1)

Introduction

a.

Describe

the end goal of your project.

We hope to achieve mail sorting

automation using the Baxter. In other words, we expect the Baxter to replace an

experienced staff in a local mail station for mail sorting jobs. Hence, the

Baxter should perform mail catching when someone hands him a mail or a small

package, sort the mail according to handwritten zip codes on the surface of the

mails, and finally pile up the mails based on size.

b.

Why

is this an interesting project? What interesting problems did you need to solve

to make your solution work?

As the eCommercial concept gains

popularity in recent years, we believe that online shopping would occupy a

large share of the market in the future. Hence, the problem of delivery goods

stands out. The current efficiency of the delivery industry will not suffice

the growing online shopping demands, and will further ruin customer experience

if delivery takes too long. Therefore, we think using robots to perform mail

sorting automation would significantly increase efficiency.

The problems that are involved with

this project includes Computer Vision for mail recognition and zip code contour

recognition, Machine Learning for mail sorting, camera sensing for AR tag

tracking and path planning and algorithm development for piling up.

c.

In

what real-world robotics applications could the work from your project be

useful?

For the mail industry. The Baxter

could work as a staff in a local mail store, so that it can catch the mails or

the packages from the customers as they hand them to him. This will allow high

efficiency in the client part of the industry. Furthermore, similar automated

sorting processes can also be applied to libraries or warehouses.

2)

Design

a.

What

design criteria must your project meet? What is desired functionality?

The project is designed to include

sensing, path planning and actuation. In more detail, our initial design is to use

the Baxter robot to build a human-robot interactive program where the robot’s

job includes:

·

Sensing

the position of the human using Kinect

·

Moving

the Baxter’s arms to get the mails from the human

·

Recognizing

the hand written zip codes on the mails

·

Putting

the mails to the corresponding regions

·

Pilling

up the mails according to their sizes

b.

Describe

the design you chose.

The final design of the mail sorting

automation project includes 3 steps. The robot first locates the handed mail.

We use AR tags to denote the size of the mails for tracking, and we set up the

camera in the Baxter's arm so that it can read information from the AR tags to

plan a path and catch the mail. And then the robot puts the mail in the correct

region according to the handwritten zip code on the mail. Machine Learning

algorithms are adopted to first recognize the contours of the digits and then

classify the handwritten digits. The classification model is a Neural Network

trained on the MNIST dataset. At last, after all the mails have been sorted,

the Baxter piles each heaps so that the order of each pile is well-organized:

biggest mails at the bottom and smallest mails on the top. Here we developed a

customized algorithm to solve the sorting problem.

c.

(And

for part d.)What design choices did you make when you formulated your design?

What tradeoffs did you have to make? How do these design choices impact how

well the project meets design criteria which would be encountered in a real

engineering application, such as robustness, durability and efficiency?

First, we decided to use AR tags to

track the mail locations. This will be unrealistic in the true mail station

setting. A better approach is to use Computer Vision to determine mail

locations and use Kinect to track human location. However, Kinect

implementation in real setting is too complicated and costly. Kinect is also

not as robust as AR tags in object locating. To improve the efficiency and the

efficacy of the entire process, we ended up using AR tags and regular cameras.

Second, in the pile-up process, we

decided to have preset locations for the mail piles and avoided reading AR tags

repeatedly. This significantly reduces the time the robot needs to locate the

mails and compute the trajectories for the pile-up phase. It also avoids the

problem that the AR tags maybe blocked by the camera view, which could

potentially impede the entire process.

Third, we used the IR sensor from

the robot's arm to determine if the mail is close enough to the gripper. This

design allows us to get closed-loop feedback on the distance between the

gripper and the mail. It improves the robustness and the durability of mail

capturing.

Four, we first wanted to use

clippers to capture the mails. Soon we figured that it would involve moving

both arms of the robot and it would not only increase the time for path

planning but also have a greater chance of not catching mails. Therefore,

suction cup was adopted instead to improve the mail capturing experience.

Results demonstrate effectiveness of suction cup over clippers.

Five, a collision object (table) was

added to the environment to avoid potential collision between the robot and the

table. The table size was set to be smaller than the actual table to make

pile-up work. Imagine having the actual table size as the collision object,

pile-up would fail every time because the gripper would find a collision when trying

to pick up a mail from the table. Adding the approximately collision object

successfully reduces the number of times the robot collide with its surrounding

environment.

3)

Implementation

a.

(And

b.)Describe any hardware you used or built. Illustrate with pictures and

diagrams. What parts did you use to build your solution?

In the project, we are mainly using the Baxter robot and its

accessory kit.

The Baxter Robot(full view):

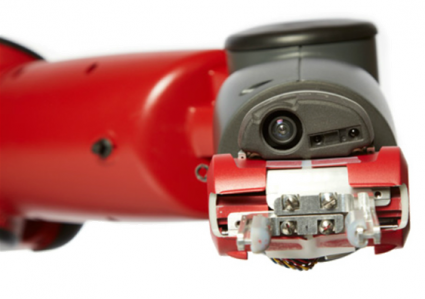

Camera with max 1280X800 resolution located in the Baxter's left

arm is used for locating the mails and providing pictures for digit

recognition.

A suction cup is installed at the end of the Baxter's left arm for

the purpose of capturing mails.

The screen on the Baxter's head is used to display the output image

of the digit recognition.

The IR sensor on the Baxter's arm is used to determine the distance

between the gripper and the mails.

b.

What

parts did you use to build your solution?(see above)

c.

Describe

any software you wrote in detail. Illustrate with diagrams, flow charts, or

other appropriate visuals. This includes launch files, URDFs, etc.

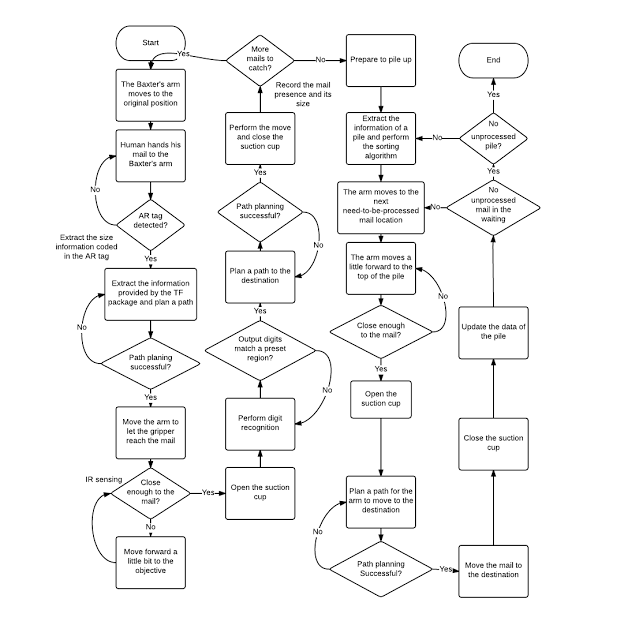

Source files: these files ensure

that the dependency and the path of the project is correct.

Mailman.py: This file is the main

frame of the working project. It contains human-computer interactive sessions,

in which the program takes in the human's order to perform different tasks.

The first session is the handover

part. In this session, the program tracks the TF messages rendered by the AR

tags, and reacts immediately to begin path planning. We implement the MoveIt!

kit to generates a plausible path by inverse kinetics. After the path has been

calculated, the gripper will move to the destination, and the IR sensor will

detect if the distance between the gripper and the mail is close enough for the

suction cup to catch the mail. If not, the gripper will automatically adjust

its pose by move forward a little bit until it reaches the mail.

The second session is digit

recognition. When catching the package, the camera located on the Baxter's arm captures

and saves a picture of the mail for the program to perform digit recognition.

If the output digits match a preset region, the Moveit! Kit will calculate a

path for the arm to move the mail to the corresponding region.

The third session is pile up. After

all the mails have been assorted to different regions, the program will first

fetch a region to begin pile up. In the mail catching process, the program

records the order of mails in each pile. We coded the mail size information on

the AR tags, so that the sorting process is based on AR tags. Our algorithm

allows three temporary zones on the table, and will perform Hanoi-Tower-like

sorting. After all the piles have been sorted, the program ends.

d.

How

does your complete system work? Describe each step.

4)

Results

a.

How

well did your project work? What tasks did it perform?

(Calculation of rates were based on the video we filmed where we

perform the entire process for multiple times.)

Our project involves five tasks:

1. Path planning:

We use the Moveit! kit and Baxter simulator as main tools to

calculate the path. To help the path planning program run stably, the preset

poses of Baxter in our program have been carefully calibrated, and the poses

enormously reduced the failure rate of generating a valid path. Our project was

carried out on the lab computer with 2 GiB memory.

Success rate

|

87%

|

2. Contour recognition:

Contour recognition is a complicated task because any other object

in the frame may be recognized as a valid contour. Therefore, in order to

reduce the contour recognition accuracy, we devised a specific pose for human

to hand the mail and the handwritten digit sizes are consistent throughout all

the sample mails for this project. Fortunately, in this simplified setting,

contour recognition gives reasonably well performance.

Success rate

|

82%

|

3. Handwritten digit recognition:

For this part, we used Machine Learning to recognize digits, and we

encountered a problem. The handwritten digit recognition works very well with

all other digits except "9".

It was because in our hand-writing, we usually choose the neglect

the hook part on the bottom of the digit "9", causing the program to

fail and output "1". This problem could be fixed by writing

"9" in a print style, but that's definitely not what we want. It

stands oppositely on the original purpose of handwritten digit recognition. To

solve this issue, we considered the situation in real life, that the Baxter has

limited arm length and hence could sort mails with limited range of zip codes.

Therefore, we decided only to track last three digits of the zip codes,

reducing the failure rate of the Baxter.

General success rate

|

74%

|

Failure rate on digit

"9"

|

89%

|

4. Suction cup + IR closed loop sensing:

The suction cup and IR closed loop sensing are originally built in

the Baxter, and we discovered that they worked stably and almost never failed.

Success rate of suction cup

|

99%

|

Success rate of IR sensing

|

99%

|

4. hand-over:

The hand-over part is a combo of all above processes. Except from

the problems mentioned above, we encountered another problem-- the Baxter arm

will overmove and hit the table(or wall/wires on the robot).We soon realized it

was a severe issue and decided to recalibrate the configuration of the Baxter.

Fortunately after reconfiguration, the failure rate was significantly reduced.

Success rate

(Every single handover is counted)

|

45 out of 78

|

Path not found failures

|

5 out of 78

|

Collision failures

|

28 out of 78

|

5. Pile-up:

In the pile up process, the algorithm we developed works well, in

the sense that the robot can figure out the correct pick up and drop off locations

for each mail. However, like hand-over process, we still met the problem of

overmove. To resolve this, we carefully calibrate the size of the table,

ensuring a successful path should be found as well as the path does not collide

with the real table.

Success rate(counting each mail

move)

|

102 out of 136

|

Overmove failures

|

34 out of 136

|

b.

Illustrate

with a video and pictures.

5)

Conclusion

a.

Discuss

your results. How well did your finished solution meet your design criteria?

Despite the data listed above, the

success rate is in fact incremented as we continuously fixed bugs and

recalibrated the Baxter. On the last 3 tests, our process ran more smoothly and

successfully avoiding most kinds of bugs.

Here is a form discussing each

design criteria.

Sensing

|

For mail locating by camera, our

implementation--AR tags and TF messages provide messages rendered to path

planning and digit recognition. The AR tags also provides the possibility for

the robot to interact with human. The IR sensing was adopted to carefully

measure the distance between the object and the gripper, and to ensure the

suction cup can work properly.

|

Moving

|

We are using the pre-installed

Moveit! Kit to perform path planning. Despite some unexpected failures(i.e.

hit table, arm entangled with wires), as we reconfigure and recalibrate the

robot, its arm moves smoothly and the gripper is able to catch the mail from

human as well as pick up mail from the table.

|

Recognizing

|

We adopted Machine Learning

techniques and used the picture rendered by the camera. Although the

algorithm failed to recognize the digit "9", all other digits were

correctly classified to mostly match the data we preset.

|

Putting

|

The regions were set manually in

order to ensure a path could be found. Since we can get a region-matching zip

code from the recognition part, the Moveit! kit can calculate a path avoiding

collisions and the arm can accurately put the mail to the corresponding

region.

|

Path Planning

|

The data above shows that we

encountered some difficulties using the Moveit! kit to calculate the path. In

the process, almost every step requires a path for the Baxter's arm to move,

and hence it is the most important part of the project. We adopted all kinds

of implementations in order to increase the success rate of path planning,

i.e. tuning parameters of the Moveit! Kit and preset poses of arms.

Fortunately, the last few tests showed that path planning worked stably

without any failures. The finished solution ensures robust user experience

with the Baxter.

|

b.

Did

you encounter any particular difficulties?

As mentioned above, we encountered

problems during the path-planning phase. At the start, the path planning

tool—Moveit! kit kept failing and could not return a valid path. We considered

about all surroundings that will influence the path plan and also thought about

the initial configuration of the program as well as the Baxter’s arm. And later

we discovered that if we gave the program more time and attempts, it will more

likely to find a valid trajectory for the arm to move, so we set the runtime of

the program to be longer than original. Also, we discovered that in the piling

up phase, the arm refused to move close to the table because the program

rejected the paths that collide with the obstacles, and hence we set the size

of the table to be smaller than actual.

And then in the real movement, the

arm kept hitting the table despite that the path shown by the program avoided

the obstacle. Another group helped us recalibrate the Baxter’s arm and

reconfigure the settings. Thanks to their help we were finally able to avoid

this issue.

Also, we encountered a problem

during the digit recognition. The digit “9” could not be recognized because in

our handwriting, we neglected the hook of the digit on the bottom. This causes

the program to read “9” as “1”. This problem could be fixed by writing “9” in a

print style, but that just stands on the opposite point of handwritten digit

recognition. Adding some of our “9”s in the training set may help the

classifier to learn better, however, this would not be a valid approach in the

real mail sorting setting. So we decided to track only the last three digits of

the zip codes. This is closer to the real life engineering setting because a

robot will not be able to sort all the zip codes in a mail sorting facility.

Instead he will only sort a range of zip codes, and the front 2 digits will all

be the same for a region. The last three digits helped a lot in increasing the

success rate.

c.

Does

your solution have any flaws or hacks? What improvements would you make if you

had additional time?

Preset poses were set to avoid path

planning failures. In this part we hard-coded the poses, but a better and more

general approach could be adopted where we don't need to preset any poses and

the Baxter will decide himself the regions to drop mails.

We still have difficulty recognizing

the mail size using Computer Vision since the mails can be handed to the robot

from different distances, so we used AR tag with coded sizes. In the future, in

the image processing process we might be able to find a formula to compute the

mail size by the contour of the mail and the IR sensing of distance, so that we

will be able to forsake the AR tags to simplify the hand-over process.

The digit recognition kept failing

on digit "9". In the future we might be able to fix it by adding more

training samples to distinguish digits "1" and "9".

a.

Names

and short bios of each member of your project

Mo Zhou – She is a graduate student in IEOR, under the supervision

of Ken Goldberg. She has taken courses like CS 189, Stats 215A, etc and has

been working on Machine Learning projects for research.

Jiacheng Wu –She is a computer science major and has taken courses

like CS 170, EE 120, etc…

Chunyu Hou -- She is an aerospace engineering major and she is an

exchange student from Harbin Institute of Technology.

Mingyi Zheng - He is a Mechanical Engineering major and has taken

courses EE C128 and has experience working on Kinect object tracking.

7)

Additional

Materials

a.

Code,

URDFs, and launch files you wrote

b.

CAD

models for any hardware you designed

Not Applicable.

c.

Datasheets

for components used in your solution

Since we did not use any additional

hardware, here we only attach the datasheets of the Baxter and its accessory

kits (provided by Rethink).

Here are the links:

d.

Any

additional videos, images, or data from your finished solution.

Video recording general mistakes: https://youtu.be/S8O9cBu0TIQ

Video specifying the mistakes happened in different phase:

e.

With

the help of Professor Ruzena Bajcsy and all three GSIs (Victor Shia, Robert

Mathew and Jaime Fernandez-Fisac), also the help from other Baxter groups (they

carefully reconfigure the Baxter so that the Baxter can move more accurately),

we finally finished this project. We would like to express our sincere

gratitude to them.